SMART MAINTANENCE OF ELECTRICAL MACHINES

ABSTRACT

Maintenance of the electrical machines is one of the most

important aspects in the power sector. As the technology is growing

correspondingly the demand for the power is also growing which results in the

increased number of generating stations, distribution stations etc...

Conventional methods of protection and maintenance are not

certain, moreover they takes long operating time. If faults are undetected, it

can lead to overheating along with catastrophic electrical failure. These

events typically require extensive repairs with an extended shutdown of the

machine. It is highly desirable to detect such faults at an early or incipient

stage so that remedial action can be taken before a complete failure occurs. With the advancement in the power electronic, embedded controllers

and sensor technology there is tremendous revolution in the field of electrical

maintenance. This paper brings to fore the various methods of electric machine

maintenance and various ways of protection of machines against overloads and

fault condition in a smart way.

Introduction

The maintenance of the electric machine is of top most priority in

the electrical power sector. The electrical power sector can be broadly

classified into generation & transmission sector and distribution sector.

The large machines used in the generation sector are “alternators”,

transformers and various kinds of induction motors are in many of the

industries. If these machines are not properly monitored it may lead to the

poor performance of the machines which is highly undesirable. Electrical

machines are used in every industry in one or the other way like “Boilers” ,

“air handlers” , “pumps” , and “cooling towers” etc…

The care taken to ensure

the proper working of these of the electrical machine is referred as “Electrical

Machine Maintenance”. our main objective in this paper is bring out smart

maintenance technique for electrical machineries which reduces the errors and

maximize the performance of the machine. We are introducing an automatic fault

detection and semi-automatic fault correction system. This system uses GSM

technology for intimating the faulty condition to the operator via SMS. By

adopting this system we can achieve better maintenance and best productivity.

Large electrical machine

Electrical machines are majorly classified as follows:

The large electrical machines which are used in the power

generation sector and industrial sector are alternator and induction motors.

Large Alternators

Turbo –

generator of 250 MVA

Need for maintenance:

The care and precautions what we take in order to make sure the

optimal working of the machine is basically refer as maintenance.

In the electrical machines the major faults are:

- Overheating of machine winding.

- Large vibration of the machine.

- Misalignment of shafts.

- Storage of large machines.

For the better operation of the electrical machine, we need to

reduce these faults to a maximum extent which will improve the performance of

the machine. Optimally maintenance of electrical machines will reduces the

losses and hence the over process of production will be economical.

Types of maintenance:

Pre- operative maintenance:

This type of maintenance is done when the machine is brought the

customer site. Some of the activities of pre-operative maintenance are:

- Visual inspection.

- Cleaning and blowing dry air.

- Checking air gap, bearing.

- Measurement of insulation resistance.

Preventive maintenance or operative maintenance:

This type of maintenance is done when the machine is operating

condition. Some of the activities of preventive maintenance are:

- Maintenance of cooling system.

- Measuring vibrations.

- Misalignment of the shafts.

- Checking for the unbalance voltage.

- Maintenance of cooling system:

Overheating of the electrical machine windings is one of the

serious issue in maintenance. the various causes for the generation of heat in

the windings are:

- Over loading the machine.

- Short circuit.

- Running the machine for the long time.

Cooling system can be broadly classified into two categories

a) Natural cooling. b)

Forced cooling.

Usually for the large machines the cooling system preferred is “forced

cooling” which consist of the air cooling or water cooling or any liquid as

coolant medium, which will be passed

through the cooling ducts manually whenever necessary.

i. 2. Measuring of

vibrations:

Whenever the machine is installed on the working site it should be

properly bolted to minimize the vibrations. Usually due to aging or some wear

and tear the nuts and bolts of the machine may become loose which may lead to

huge vibration and cause inconvenience sometime it may also cause disaster. In the preventive maintenance schedule

vibration check is done half yearly once.

3. Checking the unbalance

voltage:

Almost all large electric

machines are polyphase machines, when there is unbalance voltage or single

phase operation of polyphase machine may cause excessive overheating. It

requires only a slight unbalance voltage applied to polyphase machine to cause

large unbalance currents and results in overheating and ultimately failure of

the machine. In such case the power supply should be checked and corrected even

if there is slight unbalance is found.

Smart maintenance of

electrical machines:

In the previous section we

have seen the different maintenance schedule and their operations. We are

introducing a semi-automated maintenance system. This uses the following

components and equipment:

- Sensors.

- Embedded controllers.

- GSM module.

- Unbalance detection circuit.

Sensors:

The sensors which are used

in this system are:

1. Temperature sensor ( sensitive thermo-couple):

A thermocouple consists of two dissimilar conductors

in contact, which produces a voltage when heated. The size of the voltage is

dependent on the difference of temperature of the junction to other parts of

the circuit.

Highly sensitive Thermocouple

2. Vibration sensor:

The vibration sensor is an

electro-mechanical transducer works on principle of piezoelectric effect, which

converts the vibrational energy into corresponding electric voltage.

Embedded controller: (AT mega16

microcontroller)

Microcontrollers can sever as brain to electro-mechanical system.

It can be programmed interact with the hardware of the system and also with

user. The AT mega16 microcontrollers used here has 40 pin DIP package, Analog

to Digital converters, high speed timers and counters, and serial communication

ports etc… The pin out diagram of AT

mega16 is as shown below.

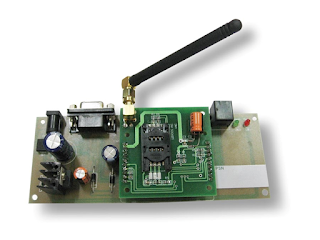

3. GSM modem:

GSM modem is a wireless

modem that works with the gsm wireless network. Sim 300 GSM modem is used for

this system which is designed with power saving technique. The sim300 is

integrated with the TCP/IP protocols, AT commands are developed to use these

protocols which are very helpful for data transfer.

GSM modem

Various AT

(attention) commands are:

·

AT+CMGW // write a message to memory.

·

AT+CMGS // send a message.

·

AT+CMSS // send a message from memory.

·

AT+CMGF =1 // set the message mode

to normal testing mode.

Unbalance detection circuit:

The transformer steps down

the 230v ac voltage to corresponding 5-0-5

v compatible with the TTL

circuits corresponding to each phase. These low power sinusoidal signals are

then half wave rectified to obtain only positive peak of cycle. Now in order to

convert sinusoidal to square pulses, analog comparator LM324 is used with the

negative threshold is set using 10k pot such that the output duty cycle is 33%

of each phase. The purpose of conversion of 33% duty cycle for each phase

because of the fact that each Phase in 3 phase supply differs with a phase

difference of 120º.

Balanced voltage supply:

The typical logic of XOR

gate is such that the output is logic high whenever the three inputs are

exactly 33% duty cycle indicating the high average value in turn means all

three phases are exactly differed by 120º.

Unbalanced voltage supply:

Considering the phase error

with overlapping and non-overlapping

pulses, the output will be a pulsed

waveform indicating the lesser average value. The principle behind obtaining

the pulsed waveform is that whenever any of the two inputs are logic high or

logic low at same instant, then output will be logic low. Thus the error in

phase is detected.

Block diagram:

Working principle:

The

block diagram of the smart maintenance system is as shown. The temperature

sensor is mounted on the machine outer body such that it form a part of the

machine winding and the vibration sensor is mounted on the foot of the machine

basement. All the output of the sensors is interfaced to the microcontroller.

The microcontroller is connected to the gsm module. When the machine is powered

up the unbalanced voltage detector circuit detects any unbalance in the voltage

or phase error. If any phase error exists then the microcontroller operates the

relay and disconnects the machine from the main supply. Whenever the

temperature raise of the machine windings is beyond the permissible limits then

the temperature sensor send a signal to the microcontroller, in turn the

microcontroller activates the cooling system available for the machine when the

machine attains the ambient temperature then the cooling system is

automatically deactivated. Due to any negative sequence or any mechanical

imbalance the vibration in the machine increased to a high value then a signal

is recorded at the microcontroller. The microcontroller buzzes an alarm and

intimates the operator.

All

the imbalance or fault conditions are automatically monitored and controlled.

With the help of the GSM modem the faulty condition is intimated to the

operator via an SMS and the operator has the flexibility to operate the

maintenance unit form the remote place.

Advantages:

·

The system modernizes the maintenance of

electrical machines.

·

Early detection of faults

·

Performances of the machine will be

improved.

·

Reliable.

Load

Specifications:

3phase,

415-440v, 8-11A, 50hz, 3.7kw, 1-5HP, 1440rpm

Limitations:

·

Initial cost of installation is quite

high.

Conclusion:

Maintenance

is very essential for any electrical machine. By adopting the automation will

yield in better result and the performance and efficiency of the machine is

improved. This system enables us to detect the fault at the earliest and hence

better protection and maintenance can be achieved.